An efficient warehouse is the key to the success of your company

Posted By: Raitis Published: 01/11/2023

Efficient warehouse setup is an important role for any company dealing with trade or storage of goods. In order to ensure effective management and service of the warehouse, you must take into account some important factors and use the most appropriate solutions for your company - lifting and loading equipment, used shelf systems, as well as the principles of their arrangement. Here are some basic tasks and suggestions for setting up your warehouse:

- Plan the layout of the warehouse: Before starting the layout of the warehouse, it is recommended to do a detailed planning. Determine what items will need to be stored, what space they will fit in, and what routes employees will need to follow to efficiently unload and ship items.

- Choose the right racking and pallet system: Depending on the type and quantity of your goods, choose the right racking and pallet system. Large quantities of heavy goods can be stored on pallet racks, which makes them easy to move and the loading process efficient.

- Arrange items according to frequency: Place frequently used items closer to loading and unloading areas to reduce employee movement. Infrequently used items can be stored away from the center of activity to make the space more visible and efficient.

- Use shelf signs and identification: Use shelf signs and clear identification systems to make it easier for employees to find the items they need. This will reduce search time and optimize work processes.

- Store heavy items on lower shelves: To prevent accidents and easy access to heavy items, store them on lower shelves. This will prevent accidents and increase employee safety.

- Store similar items together: Group similar items together to improve product findability and unloading efficiency.

- Train your employees: Ensure your employees are trained in lifting and loading techniques to reduce the risk of injury and improve work efficiency.

- Automate if possible: If your warehouse is large and turnover is high, consider automated setups and equipment such as conveyors and robots to improve operational efficiency and reduce human workload.

- The desire for efficient warehousing and material racking is critical for companies that work with large volumes of goods. By following these recommendations, you can improve warehouse operations, reduce costs, and increase efficiency.

Mezzanines / Intermediate platforms

Mezzanines / Intermediate platforms Shelves and warehouse equipment

Shelves and warehouse equipment Metal cabinets

Metal cabinets Workbenches, desks and tables

Workbenches, desks and tables Metal containers and waste management equipment

Metal containers and waste management equipment Storage boxes

Storage boxes Floor covering for workshops

Floor covering for workshops Safety equipment

Safety equipment Pallets and pallet accessories

Pallets and pallet accessories Storage racks

Storage racks Warehouse and shop trolleys

Warehouse and shop trolleys Cargo trolley

Cargo trolley Electric pallet trucks

Electric pallet trucks Electric stackers and pallet jacks

Electric stackers and pallet jacks Forklift equipment

Forklift equipment Hydraulic work tables and platforms

Hydraulic work tables and platforms Manual stackers and pallet jacks

Manual stackers and pallet jacks Pallet trucks

Pallet trucks Semi-electric stackers

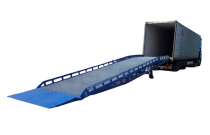

Semi-electric stackers Loading ramps

Loading ramps Dual cabinet industrial tables

Dual cabinet industrial tables Heavy duty workshop tables

Heavy duty workshop tables Laboratory cabinets

Laboratory cabinets Locker cabinets

Locker cabinets Metal shelves

Metal shelves Mobile car service cabinets

Mobile car service cabinets Mobile work tables and drawer units

Mobile work tables and drawer units Warehouse trolleys

Warehouse trolleys Workshop tables

Workshop tables Stainless steel benches

Stainless steel benches Stainless steel cabinets

Stainless steel cabinets Stainless steel shelves

Stainless steel shelves Stainless steel sinks

Stainless steel sinks Stainless steel tables

Stainless steel tables Stainless Steel Work Trolleys

Stainless Steel Work Trolleys Changing room benches

Changing room benches Clothing racks

Clothing racks Compartment cabinets

Compartment cabinets Equipment for drying clothes

Equipment for drying clothes Household lockers

Household lockers Shoe cabinets

Shoe cabinets Universal metal shelves

Universal metal shelves Filing cabinets

Filing cabinets Key cupboards

Key cupboards Mailboxes

Mailboxes Medicine cabinets

Medicine cabinets Office storage lockers

Office storage lockers Server cabinets

Server cabinets Built-in safes

Built-in safes Fireproof anti-theft safes

Fireproof anti-theft safes Fireproof safes

Fireproof safes Gun cabinets

Gun cabinets Key cupboards

Key cupboards Office safes

Office safes Laboratory desks

Laboratory desks Laboratory drawer cabinets

Laboratory drawer cabinets Laboratory fume extraction cabinets

Laboratory fume extraction cabinets Medical chairs and couches

Medical chairs and couches Medical mobile cabinets

Medical mobile cabinets Medical mobile carts

Medical mobile carts Medical Screens

Medical Screens Medicine cabinets

Medicine cabinets Sinks and their accessories

Sinks and their accessories Mobile car service accessories

Mobile car service accessories Mobile car service shelves

Mobile car service shelves Cold storage rooms

Cold storage rooms Freezer Rooms

Freezer Rooms Cold panels

Cold panels Cooling Units

Cooling Units Checkout Zones

Checkout Zones Refrigeration Equipment

Refrigeration Equipment Retail shelving systems

Retail shelving systems